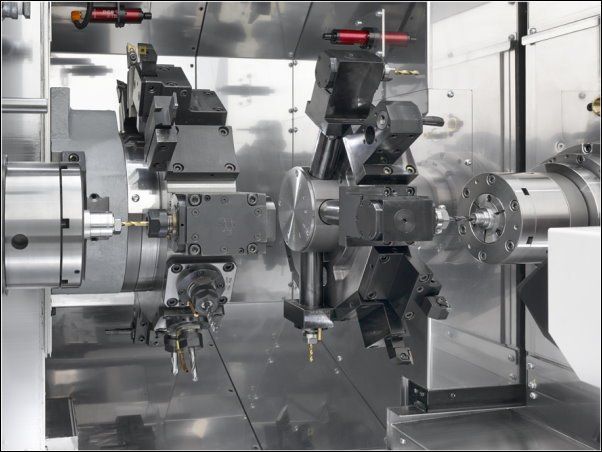

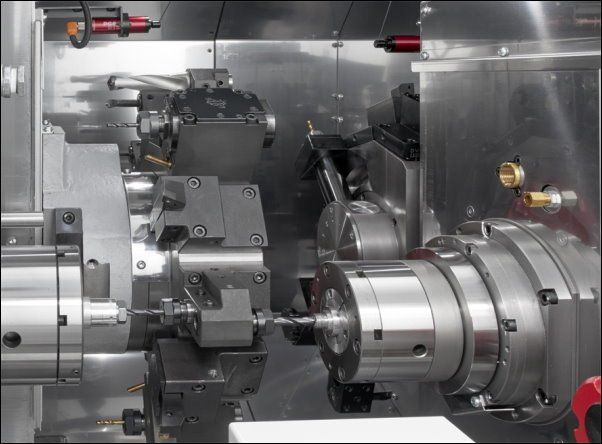

The unique design of a stationary main spindle headstock, main turret traversing on X and Y-axis, and now an 8-station back working sub-turret (with 4 live positions) provides a speedy and effective mechanism for simultaneous front and back machining.

While the main turret is working on the main spindle, the subspindle can simultaneously machine with either the main turret or secondary turret. The BNJ-51SY6 features the powerful Fanuc 0i-TF control with Cincom’s famed subspindle superimposition technology for unparalleled multi-tasking.

Equipped with 12 stations on the main turret (all live capable) and 8 positions on the secondary turret, the BNJ-series provides excellent capability and flexibility for parts up to 2” in diameter. Main turret live tool positions now increased to 25 Nm of torque! The availability of a Y-axis on main turret allows for an entirely new set of machining capabilities such as plane milling, pocket milling, and large diameter helical threading.

Like all Miyano lathes, the BNJ-51SY6 comes standard with chip conveyer, part conveyer, parts catcher, standard OD tool package, and patrol light.

Miyano BNJ-51SY6

Back-working turret design provides significantly improved cycle time...

The unique design of a stationary main spindle headstock, main turret traversing on X and Y-axis, and now an 8-station back working sub-turret (with 4 live positions) provides a speedy and effective mechanism for simultaneous front and back machining.

While the main turret is working on the main spindle, the subspindle can simultaneously machine with either the main turret or secondary turret. The BNJ-51SY6 features the powerful Fanuc 0i-TF control with Cincom’s famed subspindle superimposition technology for unparalleled multi-tasking.

Equipped with 12 stations on the main turret (all live capable) and 8 positions on the secondary turret, the BNJ-series provides excellent capability and flexibility for parts up to 2” in diameter. Main turret live tool positions now increased to 25 Nm of torque! The availability of a Y-axis on main turret allows for an entirely new set of machining capabilities such as plane milling, pocket milling, and large diameter helical threading.

Like all Miyano lathes, the BNJ-51SY6 comes standard with chip conveyer, part conveyer, parts catcher, standard OD tool package, and patrol light.

Watch the Miyano BNJ-51SY6 in Action!